Coordination

ISAH Leibniz Universität Hannover

Welfengarten 1

30167 Hannover

Project management

Dr.-Ing. Maike Beier

Tel. +49 762 2898

beier@isah.uni-hannover.de

Partner institutions

- BIORESTEC

- Göttinger Entwässerungsbetriebe

- Kommunale Nährstoffrückgewinnung Niedersachsen GmbH

- Kreisverband für Wasserwirtschaft Nienburg

- Landwirtschaftskammer Niedersachsen

- PARFORCE GmbH

- Raiffeisen Agil Leese eG

- R-E-Pro Ingenieurbüro

Dr. Sabrina Breitenkamp - SF-Soepenberg GmbH

- Stadtentwässerung Hildesheim

- Stadt Pattensen

Funding period

01.07.2020 – 30.06.2025

Webseite

Projekt sheet

SATELLITE

Process technologies in the main and satellite operation of an inter-municipal recycling center to maximize the return of phosphorus to regional agriculture

Abstract

With the concept of implementing a comprehensive inter-communal network (joint design and management of plants in regional centers (> 50,000 PE), their satellites (wastewater treatment plants < 50,000 PE) and the integration of relevant agricultural nutrient sources (liquid manure, biogas plants), the SATELLITE project offers an exemplary crystallization point for the region of Southern Lower Saxony for a long-term secured strategic investment planning for the implementation of a sustainable regional nutrient recycling for strongly agricultural regions. Through the municipal waste management association (KNRN), investment decisions of the individual plants can be strategically coordinated. The examined flexibilization options create a low-threshold access to plant technology and thus strategic freedom for the operators. The operation coordinated via the municipal association defines as management goals the provision of the optimal sewage sludge quality (calorific value, P-content) for the central recycling center at the optimal time (even capacity utilization) with the lowest environmental impact (transport), with a positive balance for the supplying regional centers at the same time. This is achieved through adapted process selection, regional recycling of recyclables and support in management.

Focus of work

SATELLITE addresses the following scientific/technical focal points by monitoring, planning and evaluating the semi- and large-scale technical investigations in project phase 1:

- Optimized operation of the regional centers regarding P-conversion/separation, degree of drainage and drying

- Use of cosubstrates in digestion

- Evaluation of N-elimination or N-recovery as well as the process adaptation of deammonification and stripping against the background of a co-treatment of economic substrates and the integration of drying

- Development and implementation of evaluation models as a basis for a strategic investment planning of the plant network under consideration of local boundary conditions, the above-mentioned optimization goals and different decision areas (regional centers + satellites, KNRN, entire region).

- Development of software-supported tools to support the operation of the regional centers, balancing of material and energy flows (regional nutrient balance including agriculture) and regulation of the input as well as the transport logistics to the central combustion.

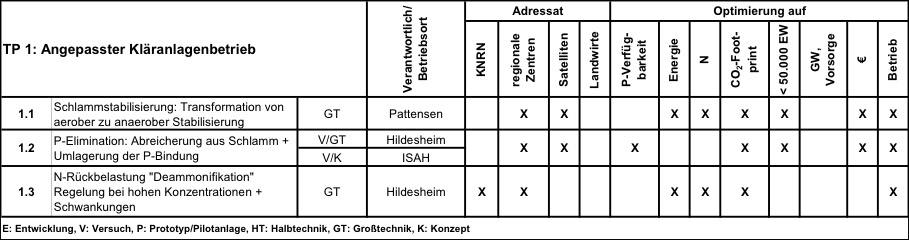

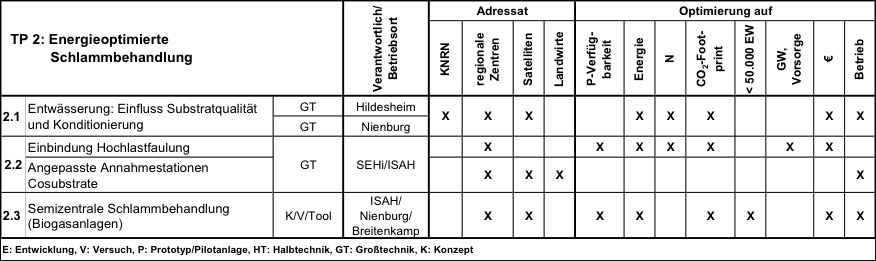

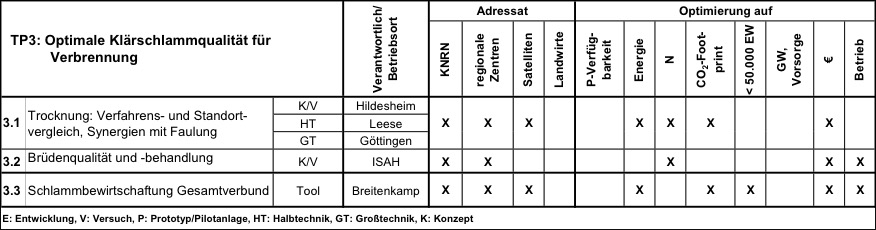

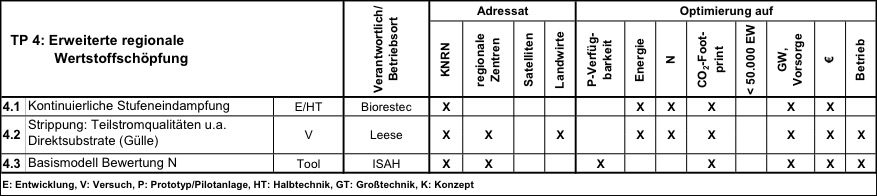

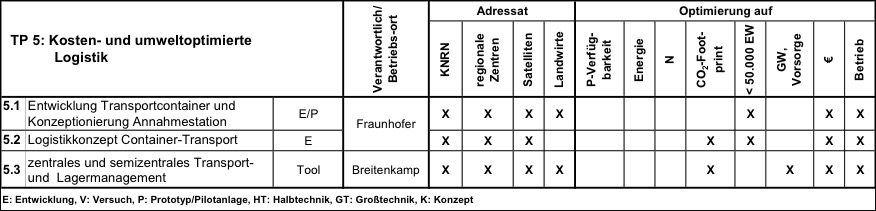

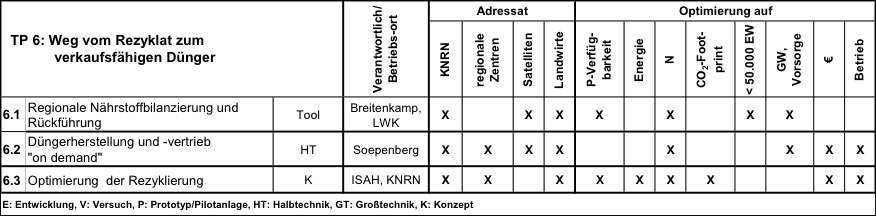

The research work to be carried out in the project is divided into 6 sub-projects and will be carried out at selected locations of the urban drainage systems of the network (LK Nienburg, Stadtentwässerung Hildesheim, Göttinger Entwässerungsbetriebe, City of Pattensen). In addition to the large-scale process testing, two test centers (Hildesheim and Leese) are operated. The district of Nienburg serves as model region. The figure shows the allocation of the different thematic subprojects to the model regions and sites.

Assignment of the subprojects to the model regions and locations in SATELLITE

Sub-work package

Contact

ISAH Leibniz Universität Hannover, Dr. Maike Beier, E-Mail: beier@isah.uni-hannover.de, Tel.: +45 762-2898

Projekt partners

Stadtentwässerung Hildesheim; Stadt Pattensen; PARFORCE GmbH

Abstract

In WP 1 the focus is on the testing and evaluation of a targeted adaptation of the operation of the wastewater treatment plants’ wastewater treatment systems with the aim of identifying the existing potential for flexibilization of the sludge quantities and qualities to be discharged with regard to the feeding of the central drying and incineration plants and to integrate it into the management strategy. Important adjustment screws are the stabilization of the calorific value of the sludge to be discharged by avoiding too extensive aerobic stabilization, the increase or active influencing of the P content and the binding form in the sewage sludge as well as the question of strategies for the co-treatment of highly loaded partial streams from drying (vapours) or sludge treatment (WP 2.3). An evaluation takes place here essentially regarding the feasibility, robustness of the procedure and the operational expenditures and costs and/or cost savings resulting from it on the sewage treatment plants.

Ansprechpartner

ISAH Leibniz Universität Hannover, Dr. Maike Beier, E-Mail: beier@isah.uni-hannover.de, Tel.: +45 762-2898

Projekt partners

Kommunale Nährstoffrückgewinnung Niedersachsen GmbH; Stadtentwässerung Hildesheim; Kreisverband für Wasserwirtschaft Nienburg; R-E-Pro Ingenieurbüro Dr. Sabrina Breitenkamp; Raiffeisen Agil Leese eG

Abstract

For further treatment in the recycling center, the sewage sludge must be preconditioned regionally in order to operate the recycling center’s systems at their optimum operating point. This means adjusting relevant sludge properties such as dry residue content, calorific value and nutrient content. Subproject 2 therefore focuses on the consideration, selection and testing of selected process technologies of regional sludge treatment regarding optimized energy utilization and economic efficiency in the overall system. This includes different concepts for dewatering and the operation of an anaerobic stage with additional acceptance of co-substrates.

Contact

ISAH Leibniz Universität Hannover, Dr. Maike Beier, E-Mail: beier@isah.uni-hannover.de, Tel.: +45 762-2898

Projekt partners

Kommunale Nährstoffrückgewinnung Niedersachsen GmbH; Göttinger Entwässerungsbetriebe; Stadtentwässerung Hildesheim; Kreisverband für Wasserwirtschaft Nienburg; R-E-Pro Ingenieurbüro Dr. Sabrina Breitenkamp; Raiffeisen Agil Leese eG

Abstract

The nature of the sewage sludge input (WP, calorific value, nutrient content) of the recycling center has a direct influence on the efficiency and economy of sewage sludge incineration and subsequent nutrient recovery. An energetically optimal utilization of the sewage sludge incineration is essential for the economic operation of the incineration and can be achieved by targeted management of the input (sludge management). Quantities and characteristics of the sewage sludge can be influenced by the regional “pre-treatment” and thus optimized in a targeted manner. Dewatering (see SP 2), digestion and drying of the sludge offer process engineering possibilities for this. This TP deals with the optimized use of digestion and drying regarding the best design of the plant park for the overall system to achieve the optimum input quality for incineration or recycling.

Contact

ISAH Leibniz Universität Hannover, Dr. Maike Beier, E-Mail: beier@isah.uni-hannover.de, Tel.: +45 762-2898

Projekt partners

Kommunale Nährstoffrückgewinnung Niedersachsen GmbH; Kreisverband für Wasserwirtschaft Nienburg; BIORESTEC; Raiffeisen Agil Leese

Abstract

By including farmyard manure in the overall concept of the KNRN, additional energy and nutrient potentials can be mobilized and made usable. Nitrogen plays a central role here. In order to make the best possible use of the nutrient potentials not only on the phosphorus side in the overall system, work package 4 deals with the recovery and utilization of nitrogen. The aim is to develop and/or test processes for the removal of nitrogen and to create a tool for process evaluation and regional strategy development.

Contact

Fraunhofer-Institut für Materialfluss und Logistik IML, Frederic Veit, M.Sc., E-Mail: frederic.veit@iml.fraunhofer.de, Tel.: +49 231 9743 342

Projekt partners

Kommunale Nährstoffrückgewinnung Niedersachsen GmbH; Kreisverband für Wasserwirtschaft Nienburg; R-E-Pro Ingenieurbüro Dr. Sabrina Breitenkamp

Abstract

With the centralization of thermal disposal and recycling for the sewage sludge network, the removal and optimized acceptance of sludge with different water content is a central logistics task. According to the current state of planning, an average of 20 truckloads of sludge per day are produced at the various wastewater treatment plants and satellites involved in this project within a radius of 150 km around the recycling center. These are to be delivered to the recycling center via different transport routes (truck, train or ship) and must be stored and processed there. If necessary, intermediate storage at the sink is useful to bundle loads and optimize the transport process.

Contact

ISAH Leibniz Universität Hannover, Dr. Maike Beier, E-Mail: beier@isah.uni-hannover.de, Tel.: +45 762-2898

Projekt partners

Landwirtschaftskammer Niedersachsen; R-E-Pro Ingenieurbüro Dr. Sabrina Breitenkamp; SF-Soepenberg GmbH

Abstract

A central element of the SATELLITE project is to bridge the gap between nutrient recovery and recycling, so that nutrients can be returned to the nutrient cycle via agriculture, decoupling spatial and temporal occurrence and demand. Against this background, TP 6 addresses the production and distribution of saleable fertilizer products from the produced recyclates (phosphoric acid, MAP/CaP, NH3 solutions of lower concentrations etc.).

Ways of exploitation

The results from SATELLITE allow all partners in the network to exploit the results directly and represent important strategic starting points for concrete follow-up activities. SATELLITE stands for interdisciplinary R&D work that will generate a multitude of new findings. The implementation partners receive concrete recommendations for action and implementation for the future design of nutrient recycling in a municipal network. The experience gained from process trials as well as key data on design and operation can be used for the individual planning of individual plant components and process steps. The management models of the overall network established in the project will contain model blocks of the tested processes with relevant key data, process dependencies of process chains as well as influences of local boundary conditions on the selected evaluation parameters (energy, CO2,eq, € and regional nutrient recycling (N,P)) and thus allow the use in investment planning and development of optimal management strategies also by other regions.