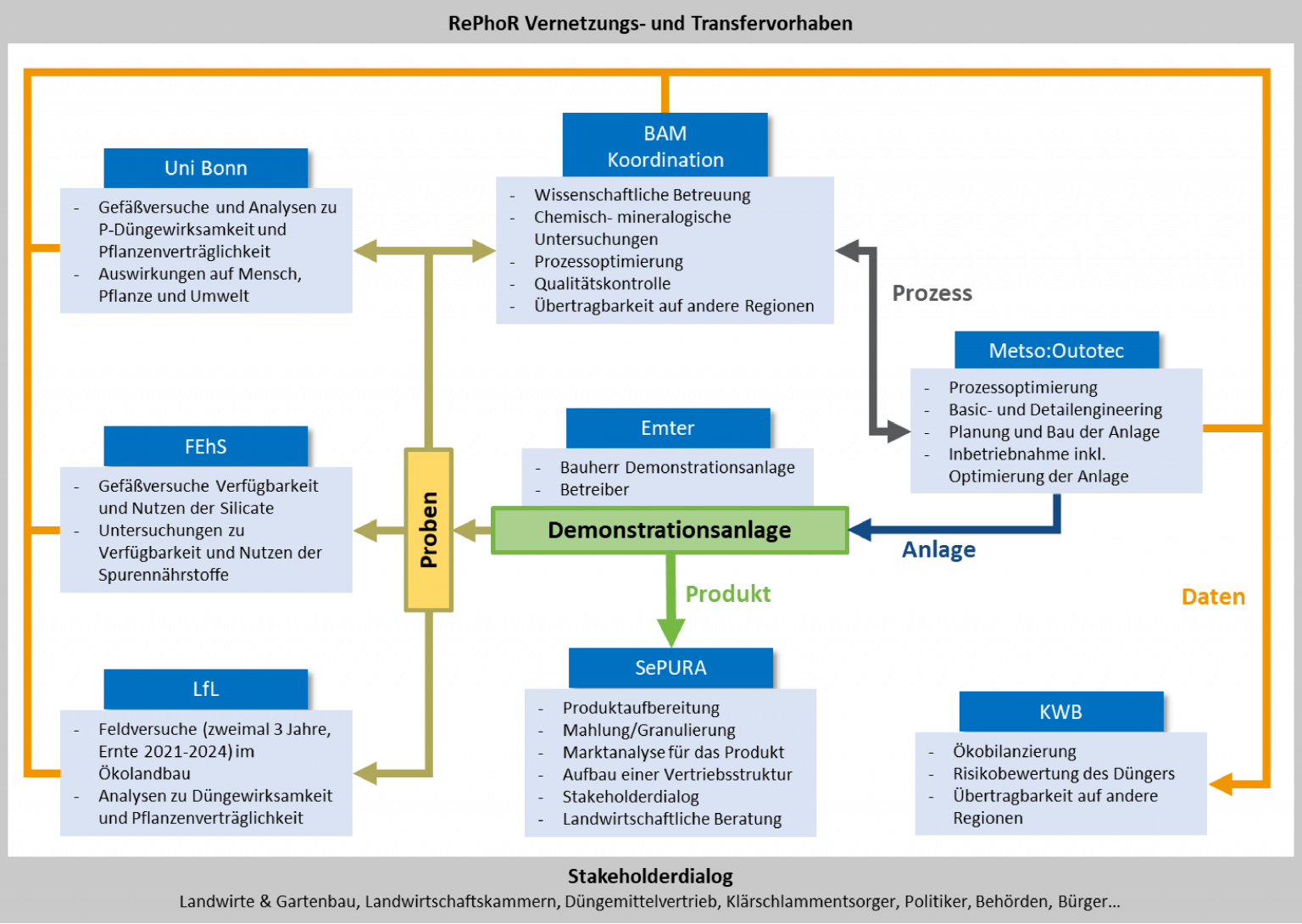

Coordination

Bundesanstalt für Materialforschung und -prüfung (BAM)

Fachbereich 4.4 Thermochemische Reststoffbehandlung und Wertstoffrückgewinnung

Richard-Willstätter-Straße 11

12489 Berlin

Project management

Dr.-Ing. Christian Adam

Tel. +49 30 8104 5670

christian.adam@bam.de

Project editing

Hannes Herzel

Tel. +49 30 8104 5680

hannes.herzel@bam.de

Partner institutions

- Emter GmbH

- sePura GmbH

- Metso:Outotec

- Bayerische Landesanstalt für Landwirtschaft (LfL)

- Kompetenzzentrum Wasser Berlin gGmbH (KWB)

- FEhS-Institut für Baustoff-Forschung e. V.

- Universität Bonn

Funding period

01.07.2020 – 30.06.2026

Webseite

Projekt sheet

R-Rhenania

Modified Rhenania phosphate from sewage sludge ash for Bavaria

Abstract

The recovery of phosphorus from sewage sludge and sewage sludge ash is a political requirement in Germany. In order to produce an effective and low-pollutant phosphate fertilizer from sewage sludge, the operator of the Altenstadt sewage sludge incineration plant (Emter GmbH) is expanding the existing mono-incineration plant to include a thermochemical process. This conversion will take place in the first half of 2024 and from summer 2024, 15.000 tonnes of thermochemical products containing highly effective phosphate compounds will be produced annually for fertiliser production. This demonstration plant will be accompanied by scientific monitoring as part of the R-Rhenania project. The project partner sePura plans to use all the fertiliser produced regionally in Bavaria.

The R-Rhenania project is also investigating a second variant of the thermochemical process with the addition of (alkaline) earths. Sewage sludge ash is thermochemically treated in a downstream rotary kiln. This process is known as AshDec®. In the second phase of the project, this process will be tested for different scenarios.

The thermochemically produced fertilisers from both variants will be characterised in detail from a chemical-mineralogical point of view and their fertilising effect will be tested in container trials as well as in field trials in organic farming. In addition to the fertilising effect of phosphate, the effects of silicates and the trace nutrients they contain on plant availability and plant health will also be investigated.

To enable the transferability of the AshDec® technology to sites with high levels of heavy metal contamination, small-scale investigations are being carried out on highly contaminated sewage sludge ashes, including engineering and cost estimates for large-scale implementation. Life cycle assessments and economic feasibility studies are also being carried out for the various applications.

Focus of work

- Construction and operation of a large-scale demonstration plant (15.000 t/a) for the production of phosphate fertiliser from sewage sludge at Altenstadt, Bavaria.

- Scientific monitoring and optimisation of the demonstration plant

- Pot trials and field trials in organic farming to determine the P-fertilising effect of thermochemical products.

- Studies on the effect of silicates and trace elements in the thermochemical products on plant nutrition and health

- Small-scale studies on the transferability of the AshDec® technology to sites with heavy metal-rich sewage sludge ash, including the design of large-scale plants.

- Life cycle assessment and economic feasibility studies for the demonstration plant and other applications of the AshDec® technology.

Work package

Contact

Hannes Herzel, Bundesanstalt für Materialforschung und -prüfung (BAM), Richard-Willstätter-Straße 11, 12489 Berlin, hannes.herzel@bam.de

Abstract

This package includes the project-internal communication as well as the communication with the networking and transfer project TransPhoR and other projects of the funding initiative RePhoR. The project results will be available to the public in the frame of workshops, information events, press releases and social media (e.g., twitter, youtube).

Ansprechpartner

Hannes Herzel, Bundesanstalt für Materialforschung und -prüfung (BAM), Richard-Willstätter-Straße 11, 12489 Berlin, hannes.herzel@bam.de

Projekt partners

sePura GmbH; Metso:Outotec; FEhS – Building Materials Institute

Abstract

Laboratory-scale experiments in crucibles and in bench-scale rotary kilns are carried out to optimize the thermochemical process and verify its input materials. These results will be incorporated into the planning and implementation of the demonstration plant. All chemical-mineralogical investigations necessary for the further work packages (especially WP 5 and WP 6) will be carried out in WP 2.

In addition, the analytics to be applied for product evaluation are to be developed for the project, especially regarding a realtime “on-site analysis” with spectrometric analysis methods, which can be used for process control.

In addition, grinding and granulation/pelletizing of the AshDec® product are investigated in order to process it into a marketable fertilizer.

Contact

Johann Emter, Emter GmbH, Alpenstraße 50, 86972 Altenstadt,

info@emter-gmbh.de

Projekt partners

sePura GmbH; Metso:Outotec

Abstract

The construction of the demonstration plant includes the financing and planning of the plant. The planning is part of other funding projects.

Contact

Tanja Schaaf, Outotec GmbH & Co. KG, Ludwig-Erhard-Strasse 21, 61440 Oberursel, tanja.schaaf@mogroup.com

Projekt partners

Emter GmbH; sePura GmbH; BAM

Abstract

After the installation of the system components, the cold commissioning begins. The entire plant is tested for its functionality. The aim is to establish operational readiness and safety, to check the function of the interfaces between the plant components and to check the function of the MSR technology. After mechanical completion (MC) and cold commissioning, the phase of hot commissioning begins, i.e. the establishment of stable operating conditions or trial operation under rated load.

Subsequently, the operation of the demonstration plant is optimized based on the findings from WP 2. It will also be checked whether further optimization potentials can be realized by the upscaled results of the small-scale investigations with focus on product quality under reasonable process parameters, in order to transfer these investigations to future commercial plants.

All samples are analysed and evaluated during hot commissioning, optimization work and subsequently during regular operation of the demonstration plant. The analyses will be based on the investigations in WP 2. The solubility of the phosphorus is determined with rapid tests at the demonstration plant (concept with spectrometric analysis methods developed in WP 2).

Contact

Hannes Herzel, Bundesanstalt für Materialforschung und -prüfung (BAM), Richard-Willstätter-Straße 11, 12489 Berlin, hannes.herzel@bam.de

Projekt partners

Metso:Outotec; Kompetenzzentrum Wasser Berlin gGmbH (KWB); FEhS-Institut für Baustoff-Forschung e. V.; Universität Bonn

Abstract

In order to examine the possibility of transferring the AshDec® technology to other regions of Germany and other countries, investigations are necessary to adapt the process for different ash qualities. The focus here is on the elimination of heavy metals in the case of contaminated sewage sludge ash and the development of appropriate technological adaption for heavy metal removal. Technical approaches in the form of chloride dosing for effective evaporation of heavy metals have already been investigated in detail by BAM and Metso:Outotec (former ASH DEC Umwelt AG). The possibilities of a simultaneous high heavy metal removal as well as a high plant availability in the product will be subject of the investigations.

For this purpose, sewage sludge ashes from German sewage sludge incineration plants and relevant sewage sludge ashes from neighbouring European countries (Switzerland, Netherlands, Austria, Poland) will be collected. The sewage sludge ashes are characterized in detail chemico-mineralogically and classified into categories for heavy metal contaminations .

Selected ashes are treated with the AshDec® process regarding the removal of heavy metals and increase of plant availability in laboratory and small-scale trials (crucible furnace and rotary kiln).

Based on these laboratory and small-scale tests, an example of an industrial-scale AshDec® plant for heavy metal contaminated sewage sludge ashes will be designed in order to compare it with alternative technological approaches. The evaluation is based on life cycle assessment and economic considerations as well as on logistical considerations such as the availability of input materials and the distribution of the products. These products from the experiments with heavy metal contaminated ashes are evaluated regarding their agronomic performance. The achieved phosphorus solubility, the heavy metal contents and other special features of the products and the regions are considered. The results of this investigation should ensure that the agronomic performance and the market for the product would also be given.

Contact

Jürgen Burkhardt, Universität Bonn, Karlrobert-Kreiten-Str. 13, 53115 Bonn, j.burkhardt@uni-bonn.de

Projekt partners

sePura GmbH; FEhS-Institut für Baustoff-Forschung e. V.; KWB; The Bavarian State Research Center for Agriculture (LfL)

Abstract

A research on potentials, regulations and practice is carried out for the applicability of the fertilizer in Bavaria. The evaluation of fertilizer law aspects is of great importance regarding a subsequent utilization or marketing of the produced phosphorus recyclates.

Investigations on the plant availability and fertilisation efficiency of the recyclates are carried out with products from small-scale production and subsequently from the demonstration plant. P release and P uptake in different crops is carried out in comparison to reference fertilizers and in dependence on different soils and crops, which are representative for the later use of the fertilizer. The soil characteristics, biomass data, nutrients and agronomic parameters required for an evaluation of the fertilization effect are recorded as well as the plant health. Investigations of pollutant release and uptake into the plant or into different parts of the plant (leaf, grain) serve to estimate the risk for the higher contaminated ashes.

Field trials will be conducted to investigate the P-fertilisation efficiency of AshDec® products under organic farming conditions in comparison with highly effective conventional P fertilizers and struvite. These will be applied at three locations in Bavaria in the three-year crop rotation of maize, winter cereals and clover grass. Two rounds will take place in the years 2021 to 2023 and 2022 to 2024.

In addition, studies will be carried out on the availability of silicon and trace nutrients (manganese, copper and zinc) for the plant, and an assessment of the positive effects on plant health will be made. Trace nutrients are essential for all plants, but if these elements are available in excessive amounts, phytotoxic and nutritional toxicological effects can occur via the soil-plant-nutrition pathway. In addition to the total content, the solubility and (plant) availability of the silicon and other trace nutrients contained in the AshDec® product are investigated and evaluated using appropriate chemical, physical and agronomic methods (pot test).

A risk assessment of the AshDec® product from the demonstration plant will be carried out, considering the release and uptake of pollutants for humans, ecosystem and groundwater. The risk assessment basically comprises the steps of hazard identification, hazard characterization, exposure assessment and risk characterization. The pollutants are evaluated individually. Based on the results, it is assessed which of the technically and economically possible operating modes are suitable for risk minimization and what degree of heavy metal reduction must be achieved for the residual risk to be acceptable or negligible.

The thermochemical product of sewage sludge ashes with sodium carbonates and also its main component calcium sodium phosphate are not yet listed in the ECHA database. Therefore, the requirements of the REACH regulation must be considered before trading the product. With a planned production volume of around 30,000 tons of the fertilizer per year, comprehensive investigations must be carried out. Key points here are human toxicity and ecotoxicity. A chemical safety report will be prepared. The results are to be published in the registration procedure.

Contact

Fabian Kraus, Kompetenzzentrum Wasser Berlin, Cicerostraße 24, 10709 Berlin, fabian.kraus@kompetenz-wasser.de

Projekt partners

Metso:Outotec; BAM

Abstract

The life cycle assessment of the demonstration plant is based on the specifications of ISO 14040/ 14044 and includes the definition of the objective and scope of the study, data collection (life cycle inventory), impact assessment and interpretation of the results. The operation of the plant is compared with a reference scenario (the direct utilization of ashes). The cumulative non-renewable energy input, the greenhouse gas potential, the terrestrial acidification potential, the freshwater eutrophication potential and the human toxicity potential are calculated as impact categories. The system under consideration includes the fertilizer production plant, transport, fertilizer application and all upstream and downstream processes influenced by the system (e.g. provision of additives or energy).

Based on the findings of the project, economic feasibility studies of the different plant types (e.g. demonstration plant versus potential plants with heavy metal removal) are carried out. These include the calculation of capital and operating costs as well as revenues over the lifetime of the plant (life cycle costing methodology). Special emphasis is placed on some factors, as they have a greater influence on the economic efficiency than others. These are likely to include different business models, capacity and type of plant, chemical and energy costs, gate fee and product revenues, and the composition of the ash (P, Si, heavy metals). These are examined in sensitivity analyses using the target parameters of net present value analysis (NPV) and break-even analysis.

Ways of exploitation

The Sewage Sludge Ordinance (AbfKlärV) 2017 limits the application of sewage sludge in agriculture in order to protect the soil, which means that in most cases only thermal recycling in incineration plants can be chosen as the disposal route. At the same time, the recovery of phosphorus from sewage sludge or sewage sludge ashes will become mandatory. Therefore, only three disposal routes remain for most of the producers of sewage sludge in the future:

- Reduction of the phosphorus content within the scope of waste water treatment to less than 20 g P/kg DM (e.g. P redissolution and struvite precipitation) and subsequent (co-) incineration of the sewage sludge in coal-fired power stations, cement works, waste or sewage sludge incineration plants. The existing processes for P-precipitation after forced redissolution do not usually achieve these requirements so far. According to previous findings, a P/kg DM of less than 20 g can only be achieved by a very high use of chemicals.

- Phosphorus recovery from the sewage sludge, with the aim of recovering at least 50% of the phosphorus or to produce a depleted sewage sludge with < 20 g P/kg DM, which can be co-incinerated.

- Incineration of the sewage sludge in mono-incineration plants with subsequent phosphorus recovery from the ashes by the plant operator, if sewage sludge with a phosphorus content of more than 20 g/kg DM is incinerated. In this case at least 80% of the phosphorus must be recovered. In addition to the AshDec® thermochemical process, wet chemical processes have also been developed which are expected to meet the targets of the Sewage Sludge Ordinance.

The current disposal emergency for sewage sludge in thermal recycling plants will be calmed in the next few years by the construction of up to 24 new sewage sludge incineration plants in Germany. For the future operators it makes sense to consider and integrate the phosphorus recovery, which will be obligatory from 2029, already during the construction of these plants. At the same time, the existing 20 sewage sludge incineration plants will have to integrate a plant for phosphorus recovery. This clearly demonstrates the economic success prospects for the AshDec® process. Furthermore, there is no phosphorus recovery process that has yet been implemented in a successfully operating large-scale plant. The AshDec® process can be regarded as very promising for the reasons stated above. AshDec® will also be used at other sites if an implementation in Altenstadt was successful.

The EU Regulation 2019/1009 of June 5, 2019 for the provision of EU fertilizer products opens the European market for the first time for recycled fertilizers, which could previously only be sold under certain national regulations. As a result, the P recyclates from the AshDec® plant in Altenstadt are expected to receive a CE mark and could be sold throughout the EU. The EU working group STRUBIAS has currently drawn up fertilizer criteria for ash-based products, among other things, which are to be incorporated into the EU Regulation 2019/1009. They will create uniform regulations for the marketing of recycled fertilizers.

Certification according to the REACH Regulation (EC) 1907/2006 is required if the product is to be approved and marketed as a product according to the European or German fertilizer regulations. SePura, as marketing and distribution partner, will decide under which regulations the product will be marketed. SePura has already sold untreated ashes from the incineration plant in Altenstadt as fertilizer (soliPur®), which are registered according to REACH regulation. Since the AshDec® process does not fundamentally change the chemical properties of the ash, it is foreseeable that there is nothing to prevent a new registration under REACH. The AshDec® fertilizer from the large-scale demonstration plant located in Altenstadt is to be distributed regionally in Bavaria by the company sePura. SePura has the corresponding network to customers in the agricultural sector. They can offer tailor-made solutions and customer-oriented advice for the application of the AshDec® product.