Coordination

Partner institutions

Ruhrverband

Kronprinzenstraße 37

45128 Essen

Project management

Hanna Evers, M. Sc.

Tel. +49 201 178-2380

hev@ruhrverband.de

- Emschergenossenschaft | Lippeverband

- Wupperverband

- Linksniederrheinische Entwässerungs-Genossenschaft

- Institut für Siedlungswasserwirtschaft der RWTH Aachen University (ISA)

- Fraunhofer-Institut für System- und Innovationsforschung (ISI)

- Institut für Energie- und Umweltforschung gGmbH (ifeu)

- Emscher Wassertechnik GmbH

- Wupperverbandsgesellschaft für integrale Wasserwirtschaft mbH

- PhosRec Phosphor-Recycling GmbH

Associated partners

- BETREM GmbH

- INNOVATHERM Gesellschaft zur innovativen Nutzung von Brennstoffen mbH

- WFA Elverlingsen GmbH

- Chemische Fabrik Wocklum│Gebr. Hertin GmbH & Co. KG

- SF-Soepenberg GmbH

- Yara GmbH & Co. KG

- WKW.group Erbslöh Aktiengesellschaft

- COMPO EXPERT GmbH

Funding period

01.07.2020 – 30.06.2025

Webseite

Projekt sheet

AMPHORE

Regional sewage sludge and ash management for phosphorus recycling for a conurbation

Bottrop wastewater treatment plant as the future site of the demonstration plant. © Emschergenossenschaft 2020, aerial photo Blossey

Abstract

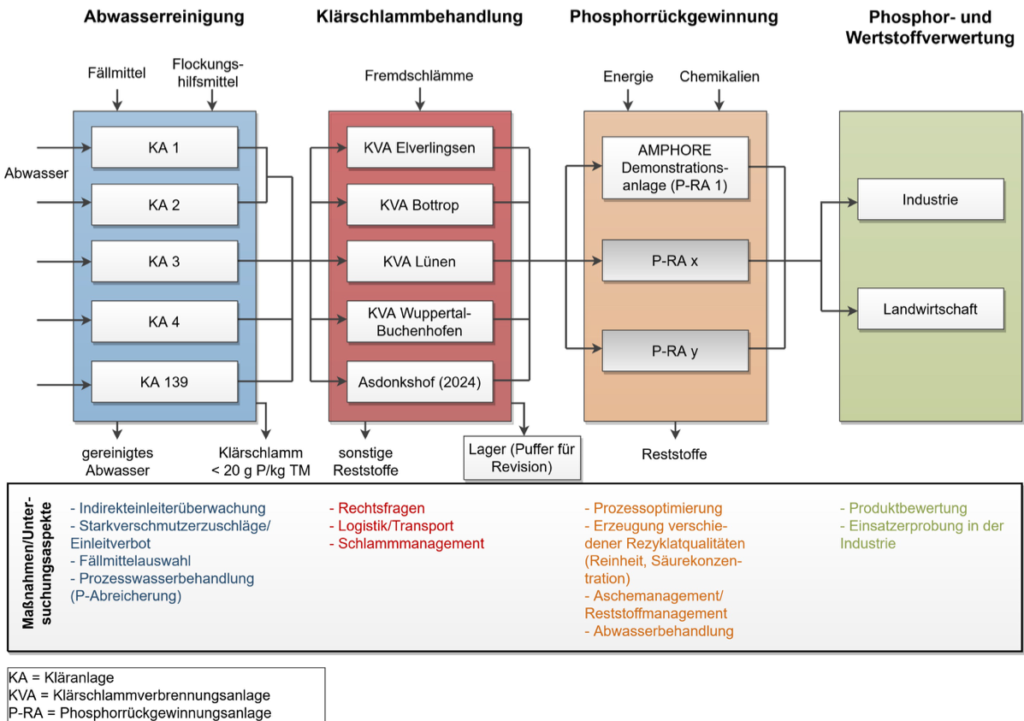

In the AMPHORE joint project, five water boards in North Rhine-Westphalia cooperate with the support of research partners, engineering offices and commercial enterprises. The size of the association with 139 sewage treatment plants and approx. 9% of the German sewage sludge production enables an innovative, region-wide management approach for sewage sludge as well as a targeted production and further treatment of ashes of different qualities. The part of the ashes that is more heavily contaminated with heavy metals is processed in a complex, wet-chemical recovery process with the aim of achieving extensive separation of pollutants and valuable substances by generating precisely fitting phosphoric acid qualities (purity, concentration) for regional customers. It is being examined whether ashes produced in a targeted manner with particularly low pollutant contents can be used in an alternative, possibly more cost-effective phosphorus recovery process. Due to the expected synergy and scale effects, significant advantages for composite solutions can be expected. In the AMPHORE project, therefore, public-law cooperation models are being examined and the cooperation of the participating water associations in the legal form of a limited liability company is being implemented as an example.

The technical core of the project is the large-scale demonstration of a wet-chemical phosphorus recovery from sewage sludge ashes (target size 1,000 t ash/a). For this purpose, a demonstration plant will be built at the combined sewage treatment plant and sewage sludge incinerator site in Bottrop, where the selected process will be optimized and examined regarding continuous operation, but also different operating conditions.

In addition to the later marketing of the produced phosphoric acid, the qualities and possible recycling paths for by-products and residual materials (including silicate residues, gypsum, metal concentrates) will also be considered in order to be able to guarantee both the highest possible quality of recycling and the highest possible disposal security (e.g. via emergency concepts, landfilling).

Landfilling of sewage sludge ashes. © Ruhrverband archive

Aim

The aim is to develop a regional concept for the implementation of phosphorus recycling around the core of an exemplary phosphorus recovery plant from ashes. For example, it will be investigated whether large, centralized plants or smaller, regionally distributed plants can be operated in a more economically and ecologically sensible way. An essential part of the considerations are also the organizational and legal boundary conditions of the entire newly oriented disposal chain.

During phosphorus recovery, in addition to the intended recyclate (phosphoric acid), various wastes and by-products are produced and a residual ash low in phosphorus remains. During AMPHORE, utilization or disposal routes for these new material flows will be developed.

Focus of work

The AMPHORE project comprises five work packages with a total of 20 subwork packages, which are described below.

Work package

WP 1.1 Network Coordination

Contact

Dr.-Ing. Yvonne Schneider, Ruhrverband, Kronprinzenstraße 37, 45128 Essen, ysc@ruhrverband.de

Abstract

Work package 1.1 covers the tasks of internal and external communication, coordination and evaluation of all processes during the entire project duration.

WP 1.2 Scientific coordination

Contact

Dr.-Ing. David Montag, Institut für Siedlungswasserwirtschaft der RWTH Aachen University (ISA), Mies-van-der-Rohe-Straße 1, 52074 Aachen, montag@isa.rwth-aachen.de

Abstract

The scientific project coordination complements the network coordination with regard to the explicitly scientific aspects of the AMPHORE project. Work interfaces are defined, methodological procedures are coordinated and the scientific exchange of all participants is supported.

WP 1.3 Communication and Dissemination

Ansprechpartner

Dr.-Ing. Yvonne Schneider, Ruhrverband, Kronprinzenstraße 37, 45128 Essen, ysc@ruhrverband.de

Project partner

All AMPHORE-Partner

Kurzbeschreibung

The results are processed in the sense of a target group-specific knowledge transfer. This includes, among other things, the central creation of practical guidelines, the integration of the results into new technical regulations, scientific publications and conference contributions as well as a project website.

WP 2.1 Basic data on wastewater treatment plants, sewage sludge and sewage sludge ash

Contact

Jennifer Hammerich, Ruhrverband, Kronprinzenstraße 37, 45128 Essen, jhc@ruhrverband.de

Project partner

Emschergenossenschaft, Lippeverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, Emscher Wassertechnik GmbH, Institut für Siedlungswasserwirtschaft der RWTH Aachen University (ISA)

Abstract

In order to create a common basis, a database is being created for the various data and information on the wastewater treatment plants, their sewage sludge, the incineration plants and their ashes. The other work packages can make use of the information from this centrally compiled data pool. An additional measuring program of the RWTH Aachen complements and condenses the results of the routine tests carried out by the associations as required.

WP 2.2: Sewage sludge and ash management

Contact

Jan-Hendrik Ehm, Institut für Siedlungswasserwirtschaft der RWTH Aachen University (ISA), Mies-van-der-Rohe-Straße 1, 52074 Aachen, ehm@isa.rwth-aachen.de

Project partner

Ruhrverband, Emschergenossenschaft, Lippeverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, Wupperverbandsgesellschaft für integrale Wasserwirtschaft mbH, PhosRec Phosphor-Recycling GmbH

Abstract

The sewage sludge and sewage sludge ash management have the goal of developing a holistic strategy for the implementation of the sewage sludge ordinance (AbfKlärV) for the project network. Here a material flow model is provided from the data raised and measured in work package 2.1. The sewage sludges and sewage sludge ashes are examined for their composition and analysed regarding their suitability for phosphorus recovery. For this purpose, the causes of certain ash properties and the effect on the recovery processes will be considered.

WP 2.3: Locations and logistics

Contact

Dr.-Ing. Issa Nafo, Emschergenossenschaft/Lippeverband, Kronprinzenstraße 24, 45128 Essen, nafo.issa@eglv.de

Project partners

Ruhrverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, PhosRec Phosphor-Recycling GmbH

Abstract

Site options for future phosphorus recovery are being investigated. It must be clarified how centralized or decentralized structures are to be evaluated spatially, infrastructural, logistically and financially. In addition, the logistical and organizational consequences of the site options in terms of transport work, on-site processes (delivery, storage, etc.) and possible synergies (e.g. coupled transports) are also considered.

WP 2.4: Organizational structure

Contact

Bernhard Kames, Linksniederrheinische Entwässerungs-Genossenschaft, Friedrich-Heinrich-Allee 64, 47475 Kamp-Lintfort, kames.b@lineg.de

Project partners

Ruhrverband, Emschergenossenschaft, Lippeverband, Wupperverband, PhosRec Phosphor-Recycling GmbH

Abstract

The aim of this work package is to evaluate the cooperation structure of the public partners selected for the implementation phase of the AMPHORE project. From this, adaptations and alternatives for a long-term implementation will be developed, involving the operators of sewage sludge incineration plants as well as the marketers of the phosphorus recyclate and by-products. The expansion of the consortium by further operators and the transferability to other regions will also be examined. The work package will be worked on under consideration of the results for the design of a common sewage sludge-ash management.

WP 2.5: Legal boundary conditions

Contact

Kirsten Allmann, Wupperverband, Untere Lichtenplatzer Straße 100, 42289 Wuppertal, all@wupperverband.de

Project partners

Ruhrverband, Emschergenossenschaft, Lippeverband, Linksniederrheinische Entwässerungs-Genossenschaft, PhosRec Phosphor-Recycling GmbH

Abstract

The planning, construction and operation of a phosphorus recovery plant as well as the regional marketing of the recyclate and by-products affect a variety of legal areas. In particular, planning and approval law, waste and chemicals law, as well as any association, public procurement, state aid and antitrust law issues that may need to be considered. The respective legal departments of the project partners emphasize the boundary conditions to be complied with and, if necessary, involve further external consultants in the respective fields. The aim is to work out the prerequisites and the aspects and models to be observed for transferability to other plant operators and case constellations.

WP 3.1: Planning, approval and allocation

Contact

Dr.-Ing. Issa Nafo, Emschergenossenschaft/Lippeverband, Kronprinzenstraße 24, 45128 Essen, nafo.issa@eglv.de

Project partner

Ruhrverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, Emscher Wassertechnik GmbH, Wupperverbandsgesellschaft für integrale Wasserwirtschaft mbH, Institut für Siedlungswasserwirtschaft der RWTH Aachen University (ISA),PhosRec Phosphor-Recycling GmbH

Abstract

First, the structured selection process for one of the two technologies pre-selected in the concept phase will be continued. For this purpose, requirements for the process and the products as well as the decision criteria for the comprehensive technical, economic and ecological assessment are specified. After selection of the technology, the planning and approval process for the realization of the demonstration plant will be initiated and then continued by PhosRec Phosphor-Recycling GmbH as the operating company.

WP 3.2: Construction of the demonstration plant

Contact

PhosRec Phosphor-Recycling GmbH, In der Welheimer Mark 190, 46238 Bottrop

Dr. Dennis Blöhse, Emschergenossenschaft/Lippeverband, Kronprinzenstraße 24, 45128 Essen, dennis.bloehse@eglv.de

Project partner

Emscher Wassertechnik GmbH, Emschergenossenschaft, Lippeverband

Abstract

As a newly founded operating company of the participating water associations, PhosRec Phosphor Recycling GmbH assumes the role of the building owner and the awarding of the corresponding service packages and organizes all necessary steps to prepare the plant for demonstration operation. This includes all steps from the preparation of the site to the construction of a hall and the integration of the plant built by the phosphorus recovery technology provider.

Arbeitspaket 3.3: Betrieb und Instandhaltung der Demonstrationsanlage

Contact

PhosRec Phosphor-Recycling GmbH, In der Welheimer Mark 190, 46238 Bottrop

Dr.-Ing. Dennis Blöhse, Emschergenossenschaft, Lippeverband, Kronprinzenstraße 24, 45128 Essen, dennis.bloehse@eglv.de

Project partner

Ruhrverband, Emschergenossenschaft, Lippeverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft

Abstract

The operation of the demonstration plant will be taken over by PhosRec Phosphor Recycling GmbH. After commissioning, a stabilization phase will follow to establish continuous operation. This is followed by campaign operation with different ash qualities and the production of different product qualities. The aim of the campaign operation is the comparison of costs and benefits of different operation modes and the determination of optimal operating conditions, which are verified in a continuous operation phase regarding the process stability.

Arbeitspaket 3.4: Wissenschaftliche Begleitung des Demonstrationsbetriebs

Contact

Dr.-Ing. David Montag, Institut für Siedlungswasserwirtschaft der RWTH Aachen University (ISA), Mies-van-der-Rohe-Straße 1, 52074 Aachen, montag@isa.rwth-aachen.de

Project partner

Emscher Wassertechnik GmbH, Wupperverbandsgesellschaft für integrale Wasserwirtschaft mbH, Fraunhofer-Institut für System- und Innovationsforschung (ISI), Institut für Energie- und Umweltforschung gGmbH (ifeu)

Abstract

The interactions between different ash qualities and the process components of the large-scale plant are investigated. The effects on the consumption of operating resources, energy requirements, total process expenditure and on the quality of products and residual materials are analysed and balanced. Furthermore, the additional efforts for phosphorus recovery from higher loaded ashes will be compared with possible measures to improve the ash quality (work package 2.2).

WP 4.1: Regional marketing of the phosphorus product

Contact

Dr.-Ing. Jutta Niederste-Hollenberg, Fraunhofer-Institut für System- und Innovationsforschung (ISI), Breslauer Straße 48, 76139 Karlsruhe, jutta.niederste-hollenberg@isi.fraunhofer.de

Project partners

Institut für Energie- und Umweltforschung gGmbH (ifeu)

Abstract

In work package 4.1 the requirements for phosphorus recyclates for demonstration operation are defined in close cooperation with the recyclate users. Specific concepts for the test phase of the phosphorus recyclates will be developed. Potential customers are the fertilizer and metal industry and, if applicable, organic agriculture. Products and by-products from the demonstration plant will be handed over to the customers in order to determine their suitability in the respective field of application. Iteratively, the test results are translated into requirements for the recyclates in the plant and product samples in defined qualities are requested for testing purposes.

WP 4.2: Regional recycling or disposal of by-products/residual materials

Contact

Dr.-Ing. Gerd Kolisch, Wupperverbandsgesellschaft für integrale Wasserwirtschaft mbH, Untere Lichtenplatzer Str. 100, 42289 Wuppertal, kol@wupperverband.de

Project partner

Ruhrverband, Emschergenossenschaft, Lippeverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, PhosRec Phosphor-Recycling GmbH, Fraunhofer-Institut für System- und Innovationsforschung (ISI)

Abstract

In this work package, regionally feasible recycling routes are developed for all by-products and residual products from phosphorus recovery in coordination with the relevant actors. The quality and thus the possibilities of use or disposal of these products depend on many factors. In particular, the technologies used and the composition of the sewage sludge ash as a basic material have a decisive influence on the quantity and quality of the products. Depending on the technology used, the following material flows are evaluated: Mineral raw material (low pH-value, high gypsum content, metal residues); chlorides containing iron and/or aluminium; treated wastewater (elevated temperature), metal concentrate, calcium hydroxide/calcium chloride.

WP 4.3: Emergency and interim storage concept

Contact

Dr.-Ing. Issa Nafo, Emschergenossenschaft/Lippeverband, Kronprinzenstraße 24, 45128 Essen, nafo.issa@eglv.de

Project partner

Ruhrverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, PhosRec Phosphor-Recycling GmbH

Abstract

Against the background of disposal safety, solutions are developed for the case of a failure of the phosphorus recovery plant and for disposal bottlenecks of the depleted sewage sludge ash. For this purpose, an appropriate emergency and interim storage concept with suitable organizational and technical measures is being developed.

WP 5.1: Variant analysis and scenario process

Contact

Dr.-Ing. Jutta Niederste-Hollenberg, Fraunhofer-Institut für System- und Innovationsforschung (ISI), Breslauer Straße 48, 76139 Karlsruhe, jutta.niederste-hollenberg@isi.fraunhofer.de

Project partner

Ruhrverband, Emschergenossenschaft, Lippeverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, Emscher Wassertechnik GmbH, PhosRec Phosphor-Recycling GmbH, Institut für Energie- und Umweltforschung gGmbH (ifeu)

Abstract

The aim of work package 5.1 is to transparently present the uncertainties resulting from the high interdependence of the subtasks and the resulting late determinations by analyzing the variants and identifying the probable scenarios, and to develop solutions that are as robust as possible on this basis. The basics for this are mainly determined in work packages 2 to 4. An analysis provides the preferred scenarios that are to be examined in more detail during the implementation phase. By combining elements of variant analysis with building blocks of a scenario process, the possible options of the AMPHORE concept will be examined, considering relevant influencing factors and changes in the environment (e.g. price developments, structural changes in agriculture, social changes).

WP 5.2: Economic valuation

Contact

Peter Wulf, Dr.-Ing. Tim Fuhrmann, Emscher Wassertechnik GmbH, Brunnenstr. 37, 45128 Essen, wulf@ewlw.de, fuhrmann@ewlw.de

Project partner

Ruhrverband, Emschergenossenschaft, Lippeverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, Wupperverbandsgesellschaft für integrale Wasserwirtschaft mbH, PhosRec Phosphor-Recycling GmbH, Fraunhofer-Institut für System- und Innovationsforschung (ISI), Institut für Energie- und Umweltforschung gGmbH (ifeu)

Abstract

The highest possible profitability of the overall system is an essential prerequisite for the design of the future regional phosphorus recycling concept. For this purpose, the existing gaps in the cost data for the scale-up of the plant technology must be closed in a reliable manner. In addition to investment and operating costs of the plant technology, costs for organization, logistics and residual waste disposal are also included. Thus, the variants and scenarios developed in the scenario process (work package 5.1) can be economically evaluated for an overall concept.

WP 5.3: Ecological evaluation

Contact

Joachim Reinhardt, Horst Fehrenbach, Institut für Energie- und Umweltforschung gGmbH (ifeu), Wilckensstraße 3, 69120 Heidelberg, joachim.reinhardt@ifeu.de, horst.fehrenbach@ifeu.de

Project partner

Ruhrverband, Emschergenossenschaft, Lippeverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, Wupperverbandsgesellschaft für integrale Wasserwirtschaft mbH, PhosRec Phosphor-Recycling GmbH

Abstract

The life cycle assessment effects of different variants for phosphorus recovery from the sewage sludge ash during a sewage sludge and ash management are evaluated in comparison to the previous sewage sludge treatment. The system framework covers thereby both the additional loads and the use, which relate to it. The evaluation is to take place differentiated in each case after individual processes and different operating supplies, in order to identify the substantial set screws and to be able to give feedback to the project partners for the ecological optimization of the entire sewage sludge utilization chain.

WP 5.4: Concrete planning of the preferred variant

Contact

Peter Wulf, Emscher Wassertechnik GmbH, Brunnenstr. 37, 45128 Essen, wulf@ewlw.de

Project partner

Ruhrverband, Emschergenossenschaft, Lippeverband, Wupperverband, Linksniederrheinische Entwässerungs-Genossenschaft, Wupperverbandsgesellschaft für integrale Wasserwirtschaft mbH, PhosRec Phosphor-Recycling GmbH, Fraunhofer-Institut für System- und Innovationsforschung (ISI)

Kurzbeschreibung

For the preferred variants for the long-term scale-up or roll-out of the regional phosphorus recycling concept, the process engineering plant components are pre-dimensioned. Possible plant locations are presented, including resulting interfaces and logistical aspects. The investments and operating costs required for upscaling are estimated (complementary to work package 5.2). Finally, an implementation schedule for the construction of the plants is outlined regarding the future requirements of the Sewage Sludge Ordinance (AbfKlärV).

WP 5.5: Transferability of the concept

Contact

Dr.-Ing. Jutta Niederste-Hollenberg, Fraunhofer-Institut für System- und Innovationsforschung (ISI), Breslauer Straße 48, 76139 Karlsruhe, jutta.niederste-hollenberg@isi.fraunhofer.de

Project partner

All AMPHORE-Partner

Abstract

In work package 5.5, the results of work packages 2, 3, 4 and 5 will be reviewed regarding their general validity and applicability in other regions as well as their usefulness e.g. in regulations or as guidelines. During the intended intensive transfer of results within the “Regional Phosphorus Recycling (RePhoR)” funding measure, a comprehensive publication of all RePhoR networks is also advisable. For the necessary generalization of the results, in addition to the process engineering solution, superordinate complexes will be further elaborated.

Ways of exploitation

In the joint project AMPHORE specific concepts for the test phase of the phosphorus recyclates are developed. Potential customers for the phosphoric acid produced in the demonstration plant are the fertilizer and metal industry and, if applicable, organic agriculture. Further details on the recycling routes are described in work package 4.